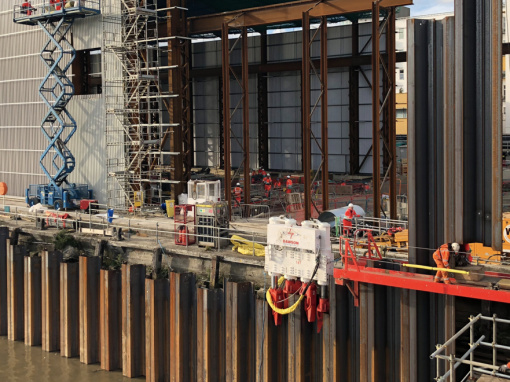

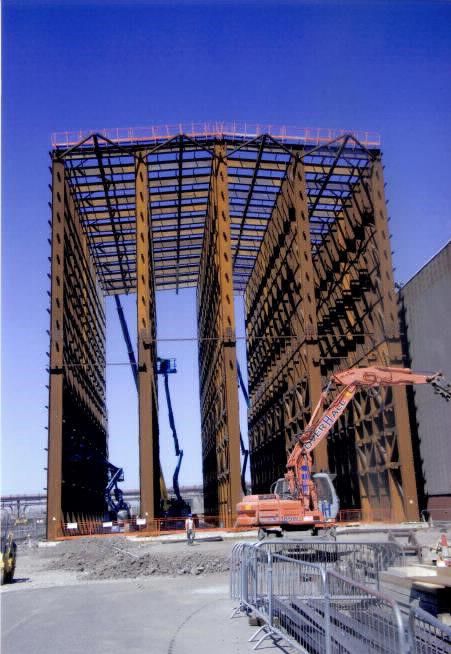

Sheet piles are used in earth retaining structures where a differential surface level is to be established. The sheet pile forms the vertical interface.

Steel sheet piles are used for both temporary and permanent retaining walls. Structures include basements, underground carparks and abutments for bridges including integral bridges.

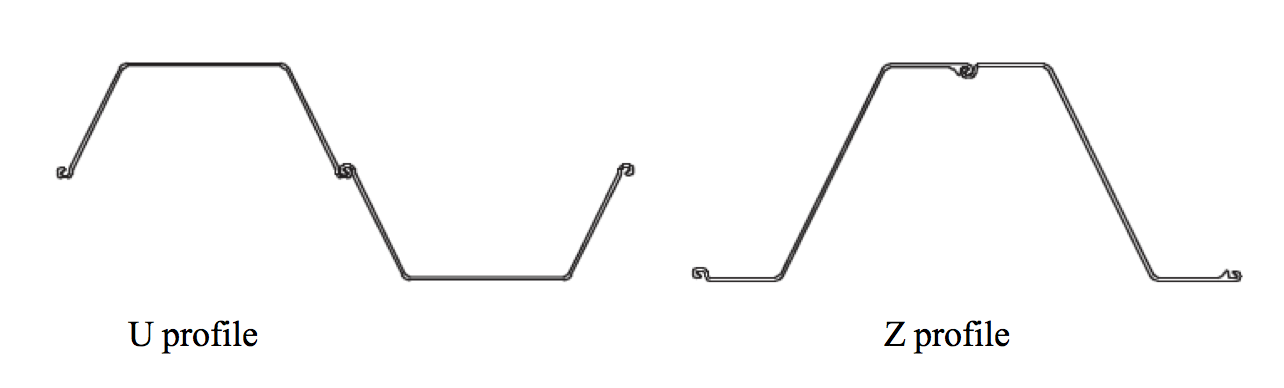

In the UK, three profiles designated as U, Z and straight web are available. They are predominantly manufactured as hot-rolled section, although cold formed sheet piles are also manufactured.

Z-profiles are used for intermediate to deep wall construction as they are considered to be the most efficient type of sheet pile available. They are commonly used for cantilever and tied-back retaining wall systems. U-profile sheet piles are used for similar applications as Z-profiles, however, because the interlock between adjacent sheet piles is at the neutral axis of the section, their bending resistances are lower than that of comparable Z-profiles.

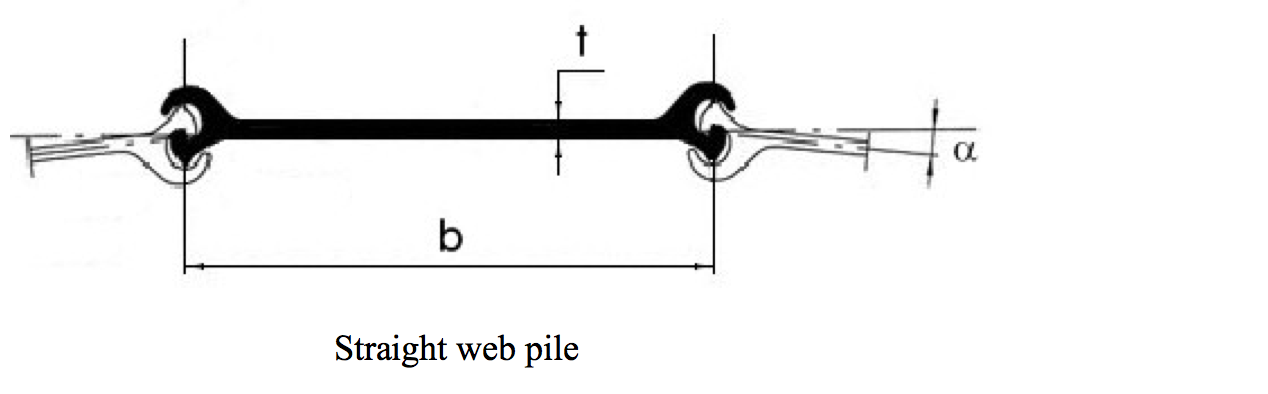

Straight web sheet piles are designed to form cylindrical structures, generally closed, retaining a soil backfill. In general, they are used where the piles are liable to be subjected to tensile forces, hence interlocking strength is of prime importance. They include cellular cell structures (cofferdams) and diaphragm cell structures.

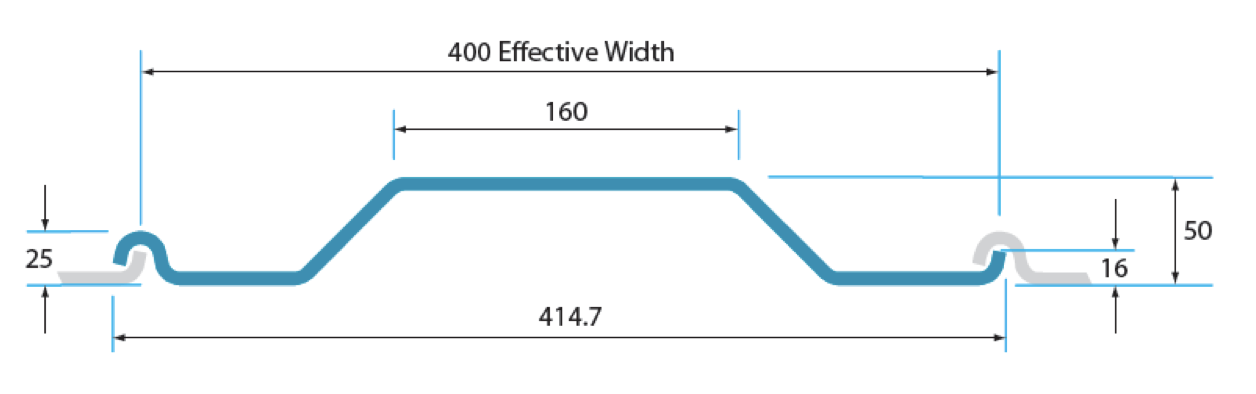

Cold formed U and Z profile sheet piles are also manufactured, however, they are primarily used for reinforcing dams and river or canal banks. They are also used for containment barriers in contaminated land and as noise barriers when sound absorbent facing is attached to the front of the pile.

Where the depth of excavation is small, cold formed trench sheet sections can be used as an alternative to U and Z sheet piles. Projects include sewerage and drainage works, and particularly sheeting for temporary works.

Steel sheet piling, including sections for box piles, is produced in accordance with BS EN 10248, including steel grades S240 GP, to S430 GP (yield strengths 240 N/mm2 to 430 N/mm2 respectively). These are hot rolled sections. Cold formed sheet sections to BS EN 10249 are also available, with typical steel grades S235 JRC to S355 JRC. A comparison of the two types of sheet piles, hot-rolled and cold-formed is discussed separately.

Steel sheet piling, including sections for box piles, is produced in accordance with BS EN 10248, including steel grades S240 GP, to S430 GP (yield strengths 240 N/mm2 to 430 N/mm2 respectively). These are hot rolled sections. Cold formed sheet sections to BS EN 10249 are also available, with typical steel grades S235 JRC to S355 JRC. A comparison of the two types of sheet piles, hot-rolled and cold-formed is discussed separately.

The advantages of steel sheet piles can be summarised as follows:

- Construction is significantly quicker than that for reinforced concrete walls.

- Permanent sheet piling is a narrow form of construction, which can be installed close up to the boundary of the site maximising usable site space.

- Steel sheet piles are suitable for all soil types.

- There is no requirement to excavate for wall foundations.

- There is no disturbance of existing ground unlike that for bored concrete piling.

- The steel components are factory quality as opposed to site quality.

- Steel sheet piles can easily be made aesthetically pleasing.

- Steel sheet piles can be placed in advance of other works.

- Immediate load-carrying capacity is present.

- Steel sheet piles can be used as curtain walling to contain the working site.

They are a sustainable product as they are extracted easily and minimise waste.

Read about Bearing Piles

Case Studies

A selection of our work

Steel Piling Group, C/O SCI, Silwood Park, Unit D, Buckhurst Road, Ascot ,Berkshire. SL5 7QN

E: info@steelpilinggroup.org

© Copyright 2018 Steel Piling Group

Terms & Conditions | Privacy Policy