Impact driving is the best method for driving piles into difficult ground or final driving of piles to level in panel form. With a correctly selected and sized hammer it is the most effective way of completing deep penetration into hard soils in most conditions. The downside is that it can be noisy and not suitable for sensitive or restricted sites.

There are several types of impact hammer available to suit the particular requirements of a site. Most impact hammers will involve a piston or ram and an anvil block with a driving cap which spreads the blow to the pile head. The machines are usually supported by a heavy frame or chassis and normally need leg guides or sleeve set up to fit snugly to the pile section being driven to maintain a vertical position during operation.

Alternatively the hammers can be set up to be supported and aligned by a leader rig. It is very important that, because of the height and slenderness of these types of hammer, the hammer is prevented from rocking or swaying when delivering powerful blows to the piles.

Hydraulic hammers totally outperform diesel hammers in terms of efficiency, are more environmentally acceptable, and are less likely to damage the head of the pile when transmitting the driving force.

Development

As excavators are commonly used on construction sites with a host of specialist attachments piling hammers are now being developed to be used as an excavator attachment, ie a plug and play system is used. The hammer is pinned to the excavator bucket linkage, which allows the driver to quickly position the hammer on to the top of a pre-driven pile. During piling the hammer is guided or crowded in the direction of the pile by the attached mechanism.

The down side of this equipment is an environmental concern, reducing the noise generated by the impact hammer system are being worked on.

Read about Pile Pressing

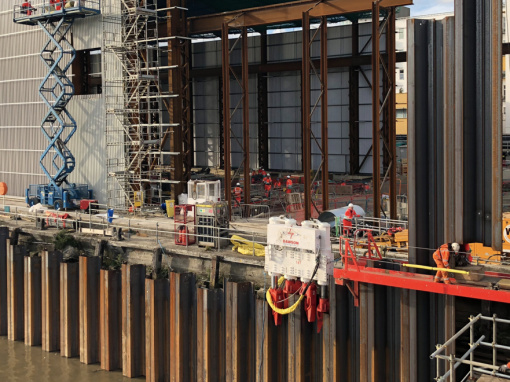

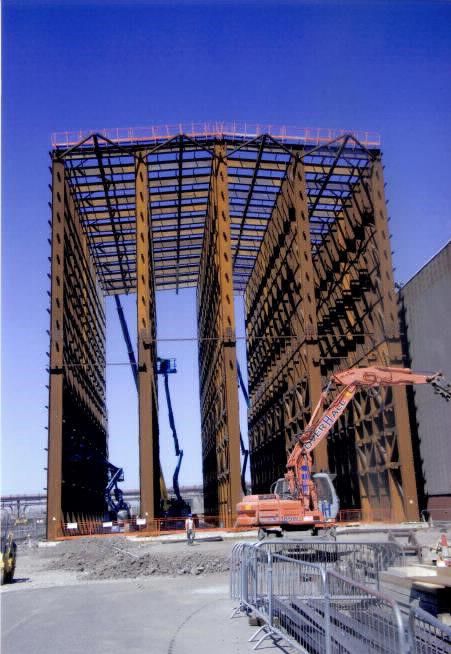

Case Studies

A selection of our work

Steel Piling Group, C/O SCI, Silwood Park, Unit D, Buckhurst Road, Ascot ,Berkshire. SL5 7QN

E: info@steelpilinggroup.org

© Copyright 2018 Steel Piling Group

Terms & Conditions | Privacy Policy