To drive or extract a pile by means of inducing a vibration in to the pile element, greatly reducing skin friction properties and allowing the pile to move through the ground with considerably less resistance than it would do under a static load.

Pile driving through vibratory means has been in existence since the 1930s with popularity increasing rapidly since the 1980s and is now the most common technique employed to drive or extract piles.

Fast rotation, out of balance, cams apply vertical vibration to the pile, liquefying granular solid and facilitating very speedy pile installation. These machines have been refined so that they can jump between frequencies and amplitude to suit the ground whilst avoiding damaging harmonic vibrations which would stress nearby structures.

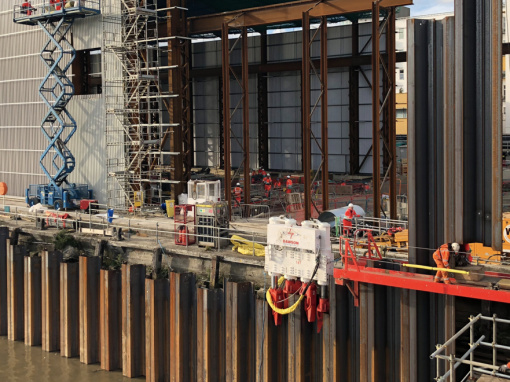

Crane suspended

The crane allows reach, often beneficial in marine works or areas where piling rig access would be problematic. It can be a lower cost option than a piling rig configuration. The largest vibrators are some 600 kgm of eccentric moment, used for wind farm mono-piles, and generally anything above 40 kgm needs to be lifted with a crane. Often a good option for vibratory pile extraction work where larger machines can be used

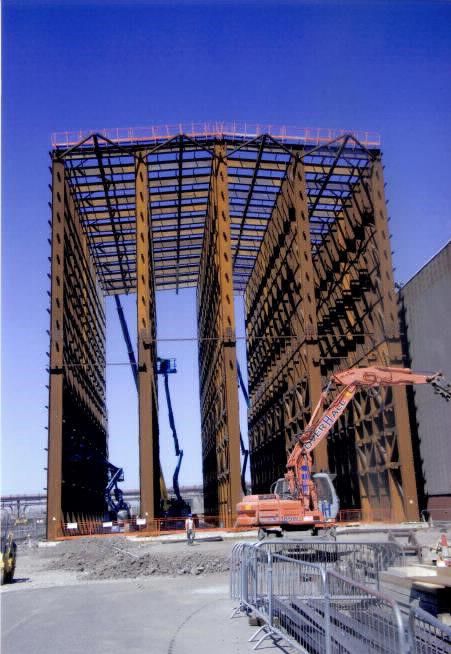

Piling rig

Almost exclusively comes with a variable moment, configured in a “vertical stack” arrangement, to create a tall thin unit capable of fitting between steel sheet piles. Typical eccentric moment ranges are from 12-40 kgm. The piling rig has the benefit of also being able to handle the piles in to position often via a lifting chain attached to the base of the vibrator. It also provides verticality and rotational control during setup and driving, eliminating much of the temporary works and guide frames associated with crane suspended operation. The net result is unrivalled production rates and a good quality end result. Having a piling rig on location also allows for other operations such as pre-augering ground treatment techniques, a commonly employed technique to aid pile penetration or extraction.

Excavator mounted

All varieties of vibrator can be found in excavator mounted variations, although the high frequency is the most common offering in the 1-12 kgm range. As a package this often is the lowest cost option. Excavators can typically reach further than a piling rig and can sometimes work in tight access area where a piling rig may be prohibited, and can also work and travel often without the piling mat restrictions associated with a rig. The length of pile that can be lifted under the excavator arm is limiting, and the quality of the installation will not match a piling rig as the verticality, alignment and power output of the vibrators are all less capable. Some manufacturers have provided solutions in an attempt to overcome the limitations of pile length and control by developing equipment with side grips and verticality control systems. These do improve the performance, although still a level below a piling rig, and partially remove the low cost benefit.

Read about Pile Extractors

Case Studies

A selection of our work

Steel Piling Group, C/O SCI, Silwood Park, Unit D, Buckhurst Road, Ascot ,Berkshire. SL5 7QN

E: info@steelpilinggroup.org

© Copyright 2018 Steel Piling Group

Terms & Conditions | Privacy Policy