The site was relatively compact with a footprint of just 30m wide by 200m long. On the long side there is a busy railway line and due care and consideration had to be made within the methodology to ensure all sheet piling works were kept within a distinct operating envelope of just 10m.

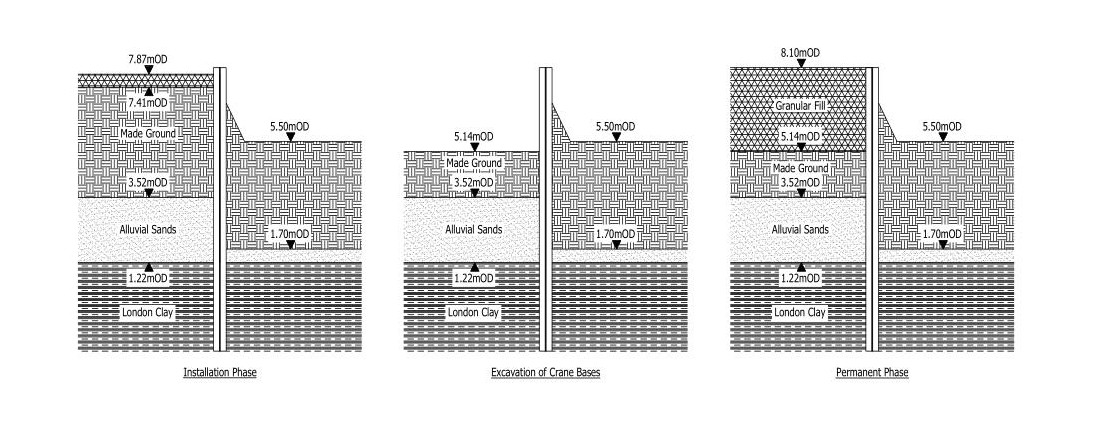

This sheet pile wall is innovative because the piles were designed with a dual purpose, working in both directions to provide temporary and permanent works solutions. In the temporary condition the piles provided restraint to facilitate construction the building, support the concrete piling mat and allow excavation of the tower crane bases on each wall / structure. In the permanent condition the piles must work in the opposite direction as a retaining wall to support a walkway along the edge of the new residential buildings sited at the top of an embankment.

The ArcelorMittal supplied sheet piles installed ranged in lengths between 7.0m GU16N and 10.0m GU21N depending upon the relevant design case. The maximum anticipated deflection (in the temporary case) is circa 24mm.

Ground Conditions

| Layer | Depth Range of Soil (m BML) | Soil Description | |

| Top | Base | ||

| 1 | 8.0 | 7.5 | Pile Mat / Designed Fill |

| 2 | 7.5 | 3.5 | Mixed Soil / Made Ground |

| 3 | 3.5 | 1.25 | Alluvial Sands |

| 4 | 1.25 | 15 | Stiff London Clay |

Installation Methodology

The piling contractor chose to install the piles with a Bauer RTG16T telescopic leader rig fitted with a high frequency city MR 150 AVM piling vibrating hammer. Due to the anticipated ground conditions, it was envisaged the pile line for the 10m long sheet piles would have to be pre-augered to loosen the substrata before driving the sheets. Vibrating hammers work well in granular materials but in cohesive soils, such as that identified in the site investigation (very stiff clay SPT N25+) often pre-augering helps with the installation process. However, using the power from the Leader Rig and the vibrator tuned to a high amplitude and lower frequency all the piles were successfully driven to level without the need any pre-augering.

The piles have a design life in excess of 120 years using a S390GP steel grade.

Fussey Piling, Unit 2, Threshers Yard, Kingham, Oxon, OX7 6YF

01608 659595

Steel Piling Group, C/O SCI, Silwood Park, Unit D, Buckhurst Road, Ascot ,Berkshire. SL5 7QN

E: info@steelpilinggroup.org

© Copyright 2018 Steel Piling Group

Terms & Conditions | Privacy Policy