The new ‘S’ stock trains that are to be introduced on the SSL network have a higher power rating than the existing fleets. Their increased tractive effort and larger auxiliary (air conditioning etc.), together with an enhanced timetable, will increase the power demand on the present SSL supply infrastructure.

To support the increased load on the Metropolitan, Circle and District Lines and the power upgrades on the deep level tube lines, reinforcement works also need to be undertaken on the 22kV and the 11kV cable distribution network. A new bulk supply point (BSP) is to be provided at the Griffith House, connecting to the DNO supply at St John’s Wood at 132kV. The BSP will house two 132/22kv double –secondary transformers and a host of other electrical equipment which includes panel switchboards, 110v batteries and chargers and metering transformers associated with the grid transformers.

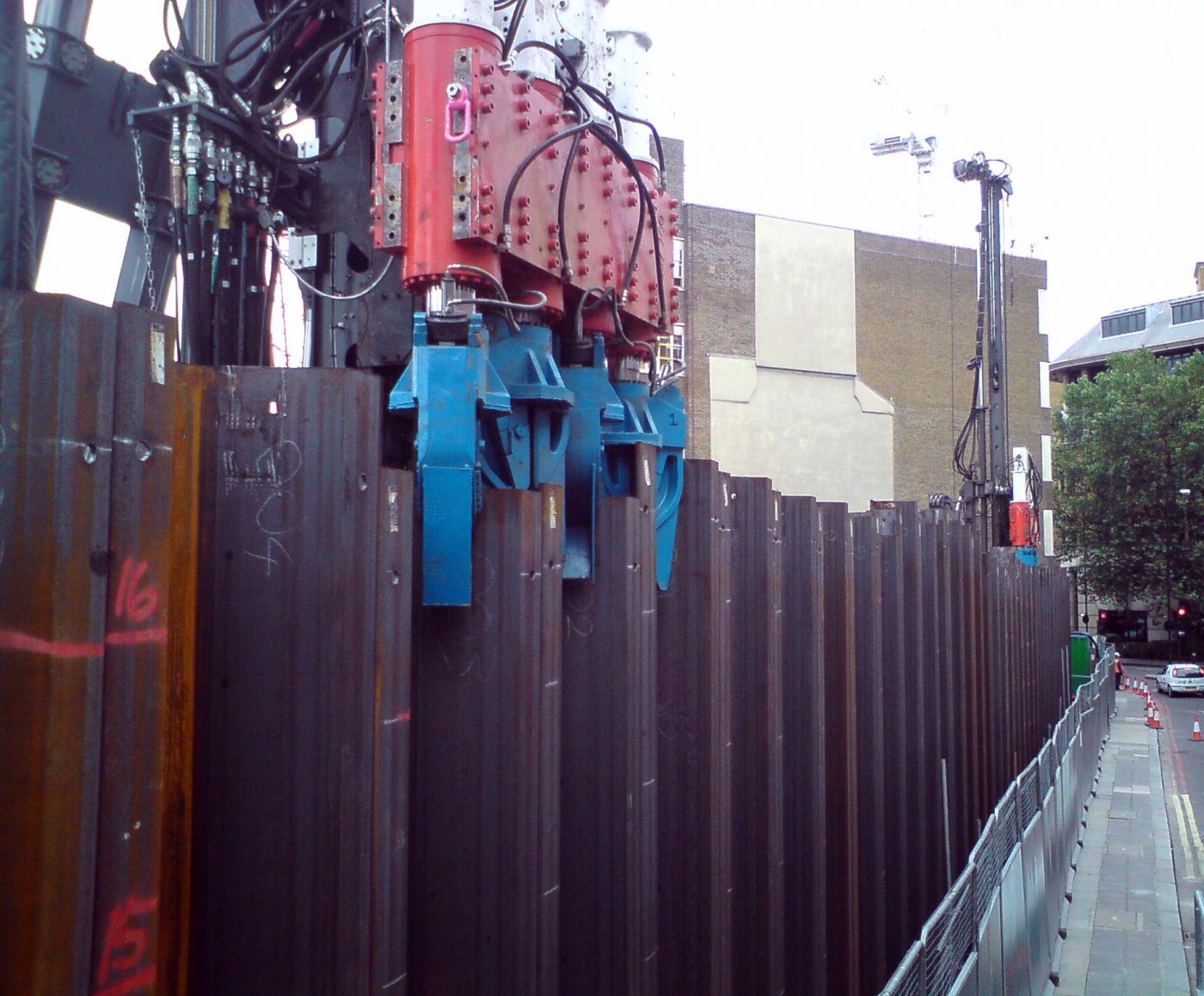

The BSP superstructure will be a reinforced concrete frame building which will consist of two sub basements levels constructed in a sheet pile cofferdam located between the railway siding at Edgware road station and Chapel Street. The sub basements will hold the switchgears while the Chapel Street level which will be about 10m high will house the transformers.

Technical Specifications

Initially the LRB125 rig commensed pre-augering work with a 300- 350mm diameter auger. Following this the LRB255 fixed mast leader rig was fitted with a resonance free vibrator. The rig pitched and guided the AZ37-700 17m piles through the previously agitated ground using the pre-stressing force of the machine assisted with the minimum vibration of 10%. The piles were pitched to a depth of more than 50% of its length or when the toe of the sheet pile had reached the cohesive soil.

The LRB125 auger rig continued moving ahead of the LRB255 until all the pre-augerwork was complete. Then the auger was removed and a 3 cylinder push pull system was fitted. The LRB125 then took up its postion as the back driving rig at the starting point of the pile line and following the LRB255 jacked the piles into the ground continuing until all piles were to level or refusal.

As soon as the last pair of the 17m long AZ37-700 sheet piles had been installed by the LRB255, the vibrator was removed and a 4 cylinder push pull system was fitted.

This followed the 3 cylinder push pull on the LRB125 jacking any remaining piles to level.

Steel Piling Group, C/O SCI, Silwood Park, Unit D, Buckhurst Road, Ascot ,Berkshire. SL5 7QN

E: info@steelpilinggroup.org

© Copyright 2018 Steel Piling Group

Terms & Conditions | Privacy Policy