Main contractor Jan De Nul carried out construction works for a gas pipeline landfall at Easington. The offshore pipeline runs for over 1200 km, making it the worlds longest.

The steel piling included several beach cofferdams and two parallel lines running out to sea. All the piles required extraction after the pipe was laid; the longest were AZ36- 630 crimped pairs at 24m, driven to refusal with a Dawson HPH 6500 impact hammer.

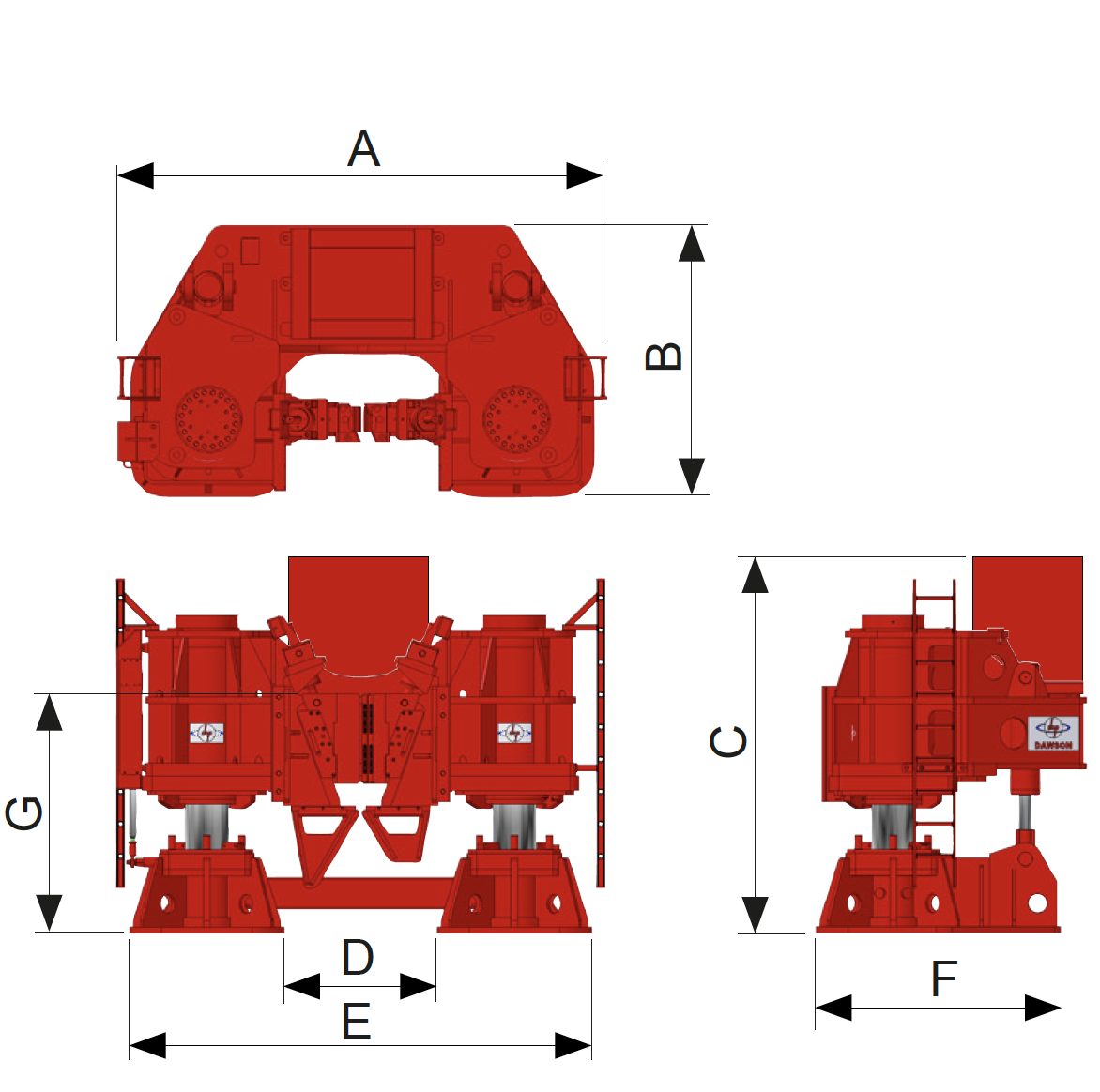

The X1000 operated for several months, its ability to apply up to 1000t of static pull force ensured it successfully extracted all the required piles, even where a PTC 100HD vibrator (2630kN centrifugal force) failed.

ADVANTAGES OF USING X1000 EXTRACTOR

- Quiet and vibration-less hydraulic pile extraction system

- 400 tonne to 1000 tonne extraction force

- Can extract ‘H’ piles, ‘U’ and ‘Z’ profile sheets. With modification it can be used to extract tubular piles.

- Typical extraction rate: 3m/min (118”/min)

- Uses the ground as reaction (as opposed to other piles) hence stand alone piles can be extracted.

- Safer than extracting piles using a vibrator or pulling with a crane.

Steel Piling Group, C/O SCI, Silwood Park, Unit D, Buckhurst Road, Ascot ,Berkshire. SL5 7QN

E: info@steelpilinggroup.org

© Copyright 2018 Steel Piling Group

Terms & Conditions | Privacy Policy