To advance the adaptation of renewable heating and cooling energy technology to thermal steel sheet piles walls, the Steel Piling Group funded a numerical analysis study and installation trial to demonstrate feasibility.

Low-carbon steel has a thermal conductivity between 40 and 50 W m-1K-1; higher than concrete, which is typically in a range of 1 to 2 W m-1K-1. As a consequence of this higher conductivity, the soil mass can potentially be more efficiently activated via a steel sheet pile wall.

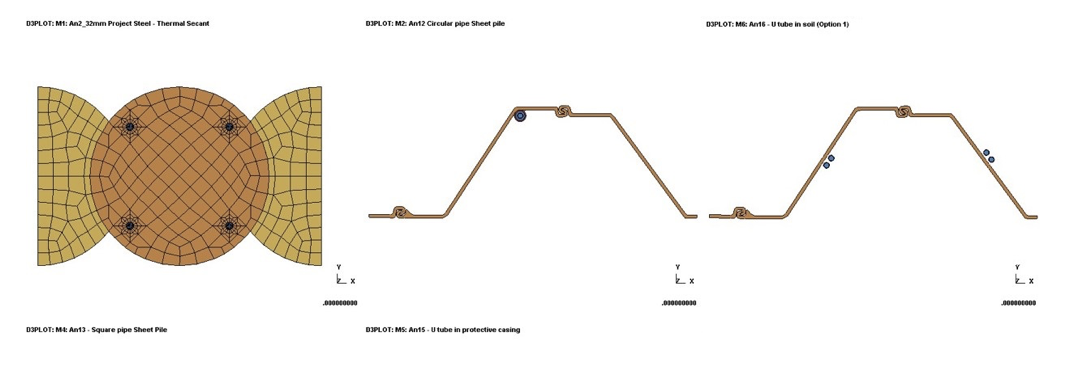

Numerical modelling was carried out with finite element program LS-DYNA to simulate thermal behaviour of steel sheet-piles and for comparison concrete secant piles, using a thermo-hydro-mechanical (THM) constitutive model to assess the cooling of the piles and the surrounding ground. The following three configurations were modelled. Secant thermal pile (u-loop) – comprising hard-firm secant piles of 750mm diameter at 600mm centres. Every secondary reinforced pile has two 25mm OD polyethylene U-loops per pile; thermal sheet pile (concentric) – consists of one concentric circular pipe per pair of AZ28-700 S355 steel sheets i.e. 1400mm centres. The concentric pipe used in the model contained a 25mm OD (Outer Diameter) polyethylene pipe encased within an outer 50mm OD steel pipe; and thermal sheet-pile (u-loop) – consists of a single U-loop adjacent to the AZ28-700 S355 sheet pile at 700mm centres. The U-loop consists of a 25mm OD polyethylene pipe.

Results

The temperature distribution (°C) for the concrete secant pile and the steel sheet piles after 100 hours of operation is shown below. At this 100hr stage, prior to reaching quasi-steady state conditions, the thermal contours show the cooling patterns for the low volume high conductivity sheet piles and the high volume low conductivity secant piles configurations.

The cumulative heat output over a period of 2,000 hours was modelled and showed a similar output of 25kWh per square metre of wall for all three configurations. The efficiency of the sheet pile systems could be further improved with additional loops or narrower sheets giving closer spacing. The analysis found that thermal steel sheet piles provide a viable alternative to traditional thermal concrete secant piles with u-tubes.

To protect the plastic u-loop geothermal tubes in the installation trial, the sheet pile was setup with a protective steel shoe at the toe and a retrievable steel shroud. The vibratory clamp at the pile head successfully drove the sheet to the targeted depth of 7m.

The study concluded that steel sheet piles can deliver similar performance to traditional secant piles.

This study was published in the November 2017 issue of the Ground Engineering journal.

Steel Piling Group, C/O SCI, Silwood Park, Unit D, Buckhurst Road, Ascot ,Berkshire. SL5 7QN

E: info@steelpilinggroup.org

© Copyright 2018 Steel Piling Group

Terms & Conditions | Privacy Policy