Main contractor Bam Nuttall selected Dawson Contract Piling to install 2 box pile bridge foundations for the planned T12 South Park entrance to the London Olympic site.

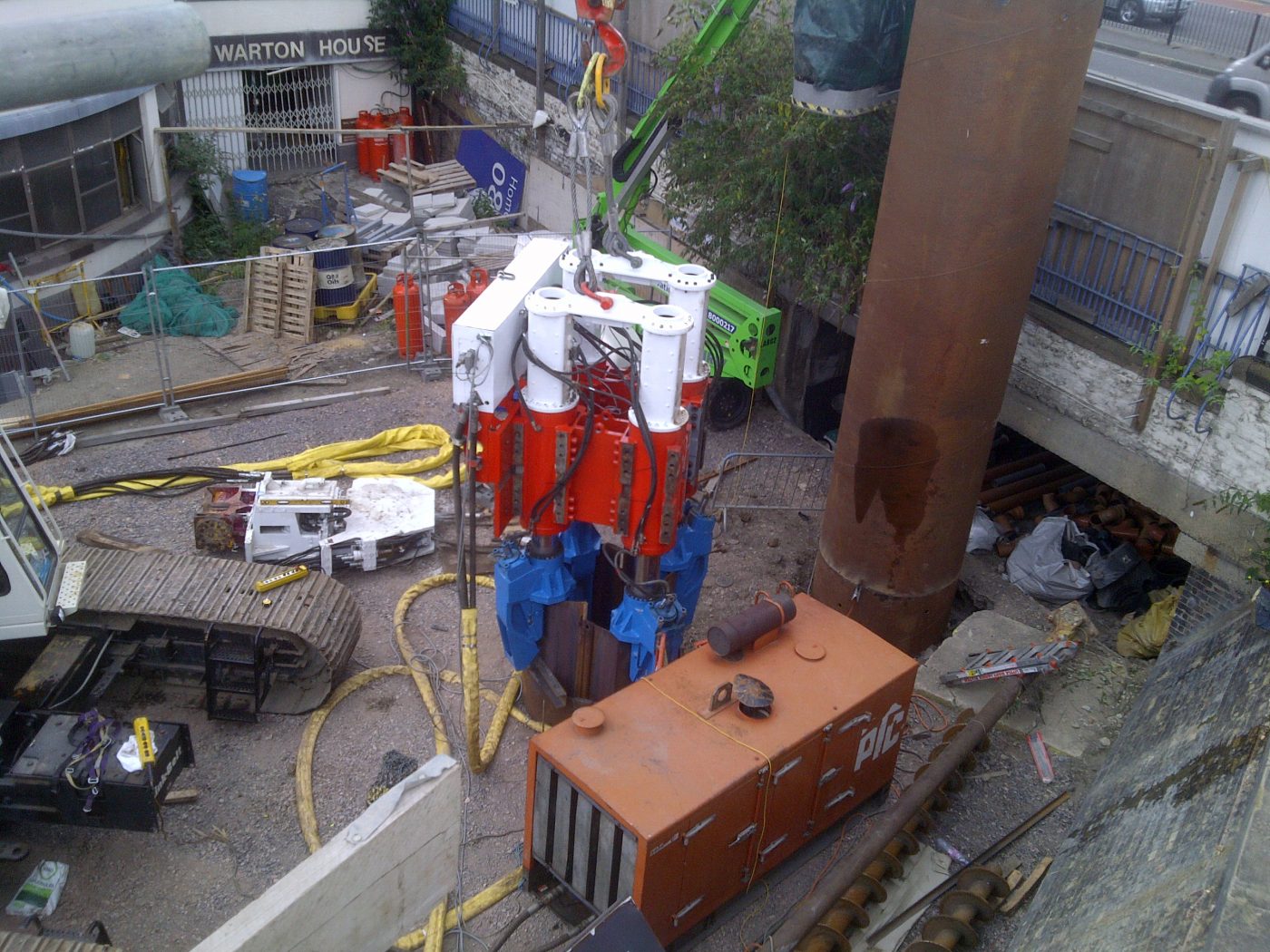

After initially driving through the made ground to the clay interface using a DCP Crane Suspended Vibro. The DCP hydraulic 4 Ram Push Pull system was then used to drive the piles to level.

This system is a quiet, vibration-less method for installation and extraction of steel sheet piles. The duration of the works was approx. 13-15 days with the actual piling work completed in 12, much to the customer’s satisfaction.

TECHNICAL SPECIFICATIONS

Due to the site restrictions the majority of the piling equipment was taken to the site area via barge.

Stage 1. The proposed pile line (box configuration) was marked out and pre-augured to the clay interface. During this stage several obstructions were encountered; these were removed. Due to the site restrictions a 360 excavator (supplied by the M.C.) was used for this work fitted with the DCP excavator mounted drill/auger.

Stage 2. 2no Casing (1.520mm Ø) @ 4m long were installed at each location to encompasses the proposed box pile, the casings were driven to .500mm above ground level using a crane suspended vibrator (twin clamp head).

Stage 3. 1no Casing (1.520mm Ø) @ 6m was butt welded onto the 1st installed casing at .500mm ground level. This acted as temporary works to position the the box pile. On top of the casing, temporary steel work was positioned to accommodate the profile of the box pile arrangement.

Stage 4. The AU25 15metre sheet piles were pitched within the temporary casing c/w interlocking omega bars to complete the box pile.

Stage 5. The crane suspended vibrator previously used to install the casings was adapted to fit single AU25 sheet piles (single clamp). The AU25 sheet piles were part driven using the vibrator through the made ground to the clay interface.

Stage 6. Once reaching the clay interface, the vibrator was changed over and the DCP Push Pull system (box pile configuration) was used. On reaching the top of the 6m casing, the push -pull system was removed. The 6m casing was cut off to allow the final drive to be completed to level refusal with the push-pull.

Steel Piling Group, C/O SCI, Silwood Park, Unit D, Buckhurst Road, Ascot ,Berkshire. SL5 7QN

E: info@steelpilinggroup.org

© Copyright 2018 Steel Piling Group

Terms & Conditions | Privacy Policy