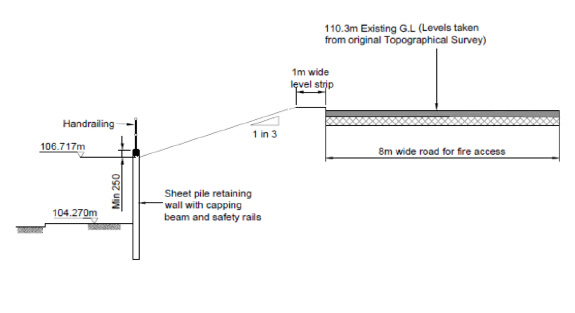

A brown field site was redeveloped by demolishing an existing warehouse and the construction of an extended distribution centre for Sainsbury’s Supermarkets. Bowmer & Kirkland Ltd appointed Fussey Piling as the sheet piling contractor to design, supply and install steel sheet piles to form a 130m long permanent retaining wall.

Ground Conditions

Structureless chalk of the White Chalk subgroup was present beneath a thin layer of tarmac. Typical N values were between 15 and 30, averaging 20. Occasional gravel and cobbles of flint were present throughout.

Groundwater was not present within the depth of the sheet piling, or encountered by the 20m deep cable percussive boreholes undertaken.

The Steel Sheet Piled Solution

Elsewhere on the site, gabion baskets, concrete gravity structures and timber crib walls were adopted. The project engineers RPS Group selected steel sheet piling for this retaining wall, based on the proximity to the site boundary and overall cost compared to other embedded retaining wall systems.

An independent Noise & Vibration Assessment was undertaken to establish the constraints on installation methods, taking into account the existing warehouse unites approximately 15m to 20m from the pile line. Fussey Piling proposed the use of one of their Bauer RTG16T telescopic leader rigs, which vibrated the piles to the required levels within a 2 week programme, using a high frequency variable moment vibrator.

Fussey Piling designed the sheet piling in-house with the aid of subgrade reaction software WALLAP, which allowed the retained slope to be accurately modelled and 120-year design life justified.

Steel Piling Group, C/O SCI, Silwood Park, Unit D, Buckhurst Road, Ascot ,Berkshire. SL5 7QN

E: info@steelpilinggroup.org

© Copyright 2018 Steel Piling Group

Terms & Conditions | Privacy Policy