Contractor Dawson-WAM selected the X1000 pile extractor to remove more than 1500 sheet piles at the prestigious Canary Wharf development in central London. The 22m (72’) long Corus LX25 piles had been driven as pairs to refusal with a 7t hydraulic drop hammer some 6 years earlier. Extraction had to be undertaken safely, without vibration and at low noise levels.

WAM’s knew the 1000 metric tonnes of extraction force would ensure the piles came out first and every time. Production was impressive, with a pile being fully extracted in 30-35 minutes.

With the additional challenge of the piles sitting in 10m (33’) of dock water a pre-fabricated frame was utilised, sitting on the dock bed, to enable the X1000 to work above water level.

WAM’s enjoyed the benefit of silent and safe extraction, as did the local residents, businesses and authorities.

Technical Specifications

| X1000 | X1000 | |

| MAXIMUM EXTRACTION FORCE | 9700kN | 1090t (US) |

| RAM SPEED | 3m/min | 118”/min |

| MAXIMUM HYDRAULIC OIL PRESSURE | 350bar | 5075psi |

| MAXIMUM HYDRAULIC OIL FLOW | 400l/min | 106gpm (US) |

| EXTRACTION DISTANCE (EACH STROKE) | 500mm | 19.7” |

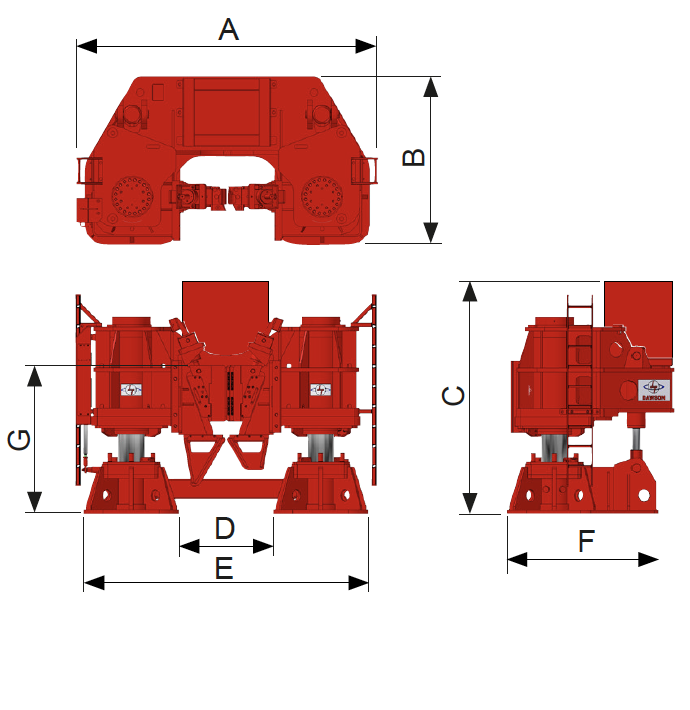

| DIMENSION A | 3780mm | 148.8” |

| DIMENSION B | 2100mm | 82.7” |

| DIMENSION C - RETRACTED | 2650mm | 104” |

| DIMENSION C - EXTENDED | 3150mm | 124” |

| DIMENSION D | 1180mm | 46.5” |

| DIMENSION E | 3580mm | 14.1” |

| DIMENSION F | 1900mm | 74.8” |

| DIMENSION G | 1524mm | 60” |

| TOTAL WEIGHT | 26500kg | 58400lbs |

ADVANTAGES OF USING X1000 EXTRACTOR

- Quiet and vibration-less hydraulic pile extraction system

- 400 tonne to 1000 tonne extraction force

- Can extract ‘H’ piles, ‘U’ and ‘Z’ profile sheets. With modification it can be used to extract tubular piles.

- Typical extraction rate: 3m/min (118”/min)

- Uses the ground as reaction (as opposed to other piles) hence stand alone piles can be extracted.

- Safer than extracting piles using a vibrator or pulling with a crane.

Steel Piling Group, C/O SCI, Silwood Park, Unit D, Buckhurst Road, Ascot ,Berkshire. SL5 7QN

E: info@steelpilinggroup.org

© Copyright 2018 Steel Piling Group

Terms & Conditions | Privacy Policy